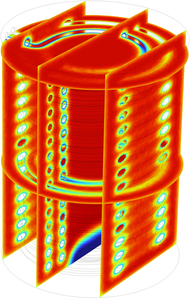

3-Dimensional Analysis of Coupled Heat and Mass Transfer in a Thermochemical Heat Storage System

1 Problem Description Most studies for investigating heat and mass transfer phenomena in sorption storage systems use 1D or 2D numerical models. These are inadequate for analyzing processes in more complex geometries used in current prototypes. We present here a 3D model for the simulation of coupled heat and mass transfer with ad/-desorption processes for a developed prototype. The prototype consists of a heat exchanger, a reactor, and a fixed bed with zeolite particles, where the reaction between the zeolite and water takes place. The heat exchanger has a 14-layered two-row helical-shaped tube. In this system, during desorption, saturated zeolite in the reactor is dried by the hot heat transfer fluid. The desorbed sorbate (water) is released in the gaseous state and enters the condenser. During adsorption, the dry zeolite in the reactor adsorbs the water vapor flowing out of the evaporator and the enthalpy of sorption is released. Both adsorption and desorption have been modeled under different boundary conditions. 2 Use of the COMSOL Multiphysics® software 2.1 Setup of the problem in the COMSOL® software The zeolite-packed bed is assumed as one porous block, with the same porosity, specific heat capacity, heat transfer coefficient, and density as the packed bed made of zeolite pellets. This assumption can significantly increase the speed of the simulation. The condenser/evaporator interfaces are modeled with constant concentration and pressure boundary conditions. The vapor is considered as an ideal gas and modeled with the Darcy equation which is valid for the low gas velocities in porous media like the adsorbent bed. Since the available Darcy model led to an over-defined condition, the formula for gas velocity in three directions has been defined in the variable section and entered in the mass transport equation. 2.2 Use of different interfaces The mass balance equation for the transport of adsorbate gas in zeolite is modeled using the available interface 'Transport of Diluted Species in Porous Media', while 'Heat Transfer in Porous Media' is considered for modeling the heat transfer between fluid, heat transfer tube, and adsorbent bed. The linear driving force (LDF) model is utilized for modeling the adsorption rate and solving the adsorbed amount, which is modeled using the available interface 'Domain ODEs and DAEs'. The flow in heat exchanger has been modeled using the 'Laminar Flow' interface. User-defined functions are written for programming the reaction kinetics and thermophysical properties expressions. 2.3 Used models from the Application Libraries Not used 2.4 Use of Application Builder, COMSOL Compiler™, and COMSOL Server™ Not used 3 Summary of obtained results A parametric study has been conducted to find the influence of different parameters and boundary conditions on the processes and the efficiency of the system. Based on the results, increasing the water vapor pressure, enhancing thermal conductivity, and decreasing the initial loading of zeolite and also improving the geometry of the heat exchanger have a big influence on improving the efficiency of the system. An efficiency of 70-80% for adsorption and desorption processes has been found. 4 Conclusions Based on the results, improvements of the storage system prototype are planned.