Numerical Study of Thermal Evaporation Unit for Phase Change of Liquid Hydrogen Peroxide to Vapor

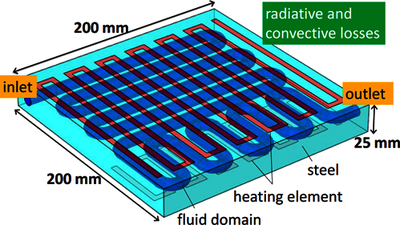

Hydrogen peroxide (H2O2) vapor is a preferred medium of sterilization in different fields of industry. Among the fact that it dissociates to oxygen and water (environmentally-friendly), H2O2 vapor possesses strong mircobicidal and sporicidal characteristics. As such, the use of H2O2 vapor as a sterilant has continuously increased in different fields of industry, like in medicine, pharma and food packaging. The described sterilization process requires a fully evaporated composition-homogenous stream of gaseous sterilant with a pre-defined flow temperature. Hence, COMSOL Multiphysics® software was used to investigate a conceptual design of an evaporation unit for the phase change to gaseous form of an aerosol containing H2O2. Process parameters such as heating power defined as an input current to the meander-type heating element were examined. In addition, the design of the unit was investigated, in which a complete evaporation of a 35%-weight H2O2 solution is required at the outlet with a temperature of approximately 150 °C.

Download

- jildeh_presentation.pdf - 1.59MB

- jildeh_poster.pdf - 1.01MB

- jildeh_abstract.pdf - 0.51MB